MEIDEN NANOPROCESS INNOVATIONS INC., located in Chiba, Japan, holds significant expertise in the technology of high-concentration and high-purity ozone generators. Ozone, with its varied applications, ranges from disinfecting water and medical equipment to playing a crucial role in surface modification and film formation within the semiconductor industry.

In July 2023, at the 23rd International Conference on Atomic Layer Deposition (ALD 2023) held in Bellevue, USA, the company presented interesting results from studies using their cutting-edge pure ozone generator in metal oxide ALD thin film formation.

The pure ozone generator produces extremely high concentration (>90% wt %), high purity, and long lifetime ozone gas when compared to conventional ozone generators. The study showed that this pure ozone gas enhances film formation in the ALD processes.

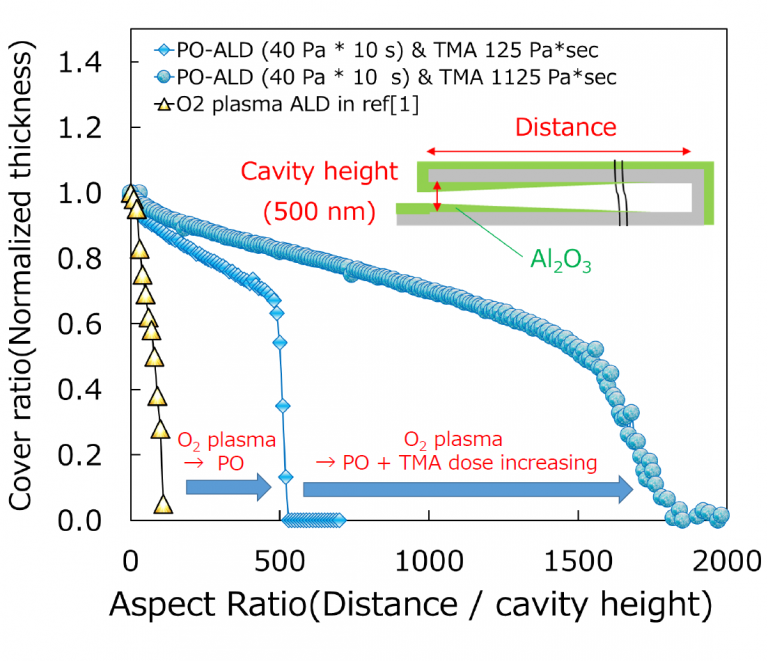

Utilizing the PillarHall® LHAR4 test chip and its measurement method, MEIDEN NANOPROCESS INNOVATIONS demonstrated that using pure ozone as an oxygen precursor can enhance film penetration depth over 10-fold compared to oxygen plasma. Furthermore, conformal deposition on the ultra-high aspect ratio of 1500:1 was achieved (Fig 1).

Figure 1. The film penetration depth profiles extracted from PillarHall® experiments for PO- (pure ozone) and O2 -plasma as oxygen precursor with TMA in ALD Al2O3 processes.

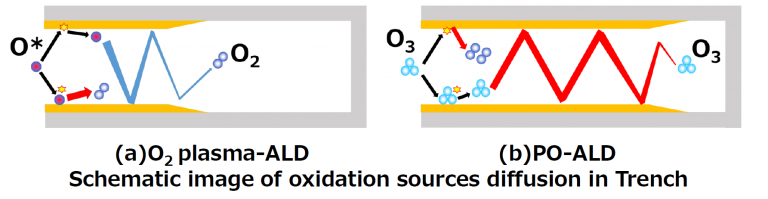

The findings indicated that utilizing pure ozone as an oxidation gas, with its long lifetime and high concentration, supports conformal film growth even in extremely high aspect ratio cavities, without modifying essential film properties like growth per cycle and dielectric constant. This phenomenon can be explained through reaction kinetics where diffusion, surface coverage, and oxygen radical collisions in the narrow cavity vary between oxygen plasma and pure ozone, as illustrated in Fig 2.

Figure 2. The suggested pathway for how the pure ozone (PO) gas improves the film growth in high aspect ratio trenches compared to oxygen-plasma.

Dr. Naoto Kameda from MEIDEN NANOPROCESS INNOVATIONS INC. shared, “There is an increasing need for deposition of high-k oxides onto high aspect ratio cavities such as in 3D-NAND and MEMS. Our pure ozone generator technology is one of the key solutions since it enables super-conformal films in low temperatures, as tested with PillarHall.”

The PillarHall LHAR test chip is a product of Chipmetrics Ltd, Finland. Dr. Mikko Utriainen, CEO of Chipmetrics, noted, “Fast and accurate PillarHall LHAR test chip is a widely used thin film characterization tool among ALD process and its 3D application developers. Therefore, it is fascinating to see PillarHall being used also in ozone generator development.”

Meidensha’s case demonstrates that PillarHall will continue to find increasing applications in semiconductor tool development and qualifications. For more information about the pure ozone generator technology by MEIDEN NANOPROCESS INNOVATIONS INC, visit https://www.meidensha.co.jp/npi.

For more information of PillarHall test chip and method, visit https://www.chipmetrics.com or send your request to [email protected]

REFERENCE

[1] Film Conformality and Extracted Recombination Probabilities of O Atoms during Plasma-Assisted Atomic Layer Deposition of SiO2, TiO2, Al2O3, and HfO2

K. Arts, M. Utriainen, R. L. Puurunen, W. M. M. Kessels, H. C. M. Knoops, J. Phys. Chem. C 123 (2019), 44, 27030-27035, https://pubs.acs.org/doi/10.1021/acs.jpcc.9b08176