The recent ALDALE 2023 conference in Bellevue witnessed the growing use of PillarHall chips in thin film conformality research. It was remarkable to see PillarHall applied to answer fundamental research questions and aid in the development of new process technologies for high aspect ratio challenges and 3D nanodevice applications. Here, we summarize our key pick-ups from the ALDALE 2023 thin film conformality research.

FUNDAMENTAL CONFORMALITY RESEARCH

APPLICATIONS OF PILLARHALL

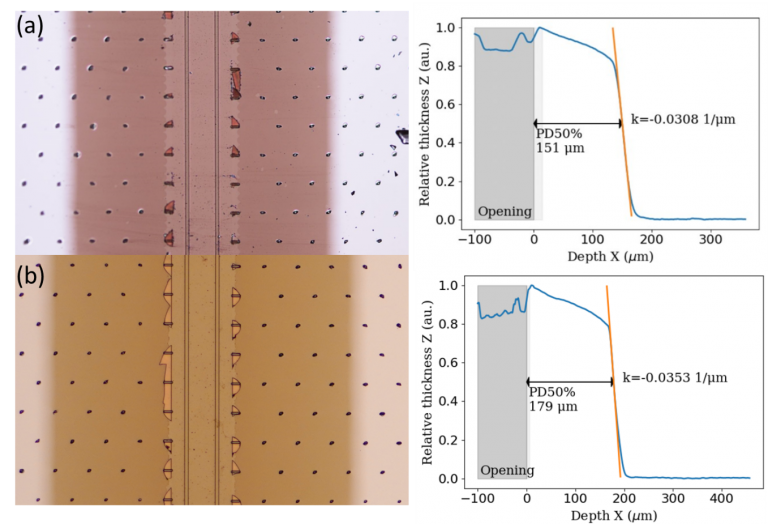

The film penetration depth profile obtained from PillarHall LHAR4 test chip (right panel) and the optical microscope images (left panel). PD50% (penetration depth at 50% of initial thickness) is indicated as well as the slope (k) at PD50%.

(a) ALD Al2O3 result without pre-treatment.

(b) ALD Al2O3 results from 2 minutes O2 plasma treated PillarHall LHAR4 chips.

In both cases thermal ALD (420 cycles to yield ≈50 nm Al2O3 film) at 300 °C was performed using a pulse/purge sequence as follows; 0.15 s TMA / 1 s purge / 0.15 s H2O / 1 s purge.